STORM Resources

Recent Newsletters

Click Here to Read! Click Here to Read! | May 2024 – Identifying and Capitalizing on Opportunities Coming Out of an Outage When coming out of outages it is not uncommon to realize that issues have developed or are still present and have gotten worse from before the outage. The immediate cause of these issues is often not clear from just the control room indications. However, testing the system inputs can help reveal the issues. This testing includes airflow testing of the primary, secondary, and overfire air to ensure accurate flow measurement and control, as well as correct flow rates and proportions of air to each location. Mill performance testing involves assessing fineness, distribution, and air-to-fuel ratio. Flue gas testing is also conducted to review the temperature distribution and flue gas constituents, which can help identify problem burners, air-in leakage, or incorrect O2 indications that the unit is controlling from. Click to find out more! |

Click Here to Read! Click Here to Read! | Airflow measurement plays a major role in the operation and control of all types of combustion systems. Storm has tested, calibrated, designed, and tuned nearly every type of airflow measurement device available. This summary provides an overview of the importance of accurate primary airflow measurement and control along with issues that arise when not tuned properly. Primary airflow serves multiple purposes in direct-fired pulverized coal systems. Click to find out more! |

Click Here to Read! Click Here to Read! | November 2023 – Identifying Air In-Leakage! Air in-leakage is a subject all power plant personnel have heard about but often gets overlooked. Due to typically developing over a long span of time, the negative effects of air in-leakage are often not observed until it is too late, resulting in unit derate, increased slagging, and increased dry gas losses. This short newsletter aims to dive into demystifying air in-leakage by giving you the tools to understand what air in-leakage is and where it typically occurs, how to find it, and the benefits of reducing air in-leakage. |

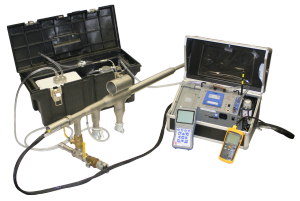

Click Here to Read! Click Here to Read! | May 2023 – HVT Testing is Still Important! HVT testing is a method to measure and optimize the performance of boilers by using water-cooled probes to measure flue gas temperature and composition at the furnace outlet. It can help plant operators to adjust the oxygen levels for combustion and reduce emissions, slagging, corrosion, and spray flows. HVT testing is still essential despite newer technologies because many boilers in the USA are old and have inaccurate oxygen indicators. HVT testing can also help with regulatory compliance and boiler longevity. |

Click Here to Read! Click Here to Read! | April 2023 – Testing Efficiency Improvement with SOAR System With emission limits growing ever tighter, efficient combustion is a necessity for most boilers to meet these lower limits. Well-tuned units are achievable when all equipment is kept in good operational condition. Many plants face a variety of tuning challenges, and it is important to keep the boilers operating efficiently and reliably. This becomes even more of a challenge when once base-loaded plants are required to chase load demand due to the increase of renewable power on the grid. When it comes to combustion tuning, STORM’s automated flue gas sampling system is a great tool. It allows for more firing combinations and tuning adjustments to be made and tested in shorter timespans over the traditional manual traverses of the flue gas after the furnace exit. What does this mean for you and your plant? With the improvement in testing efficiency, your dollars spent on testing go further. Our SOAR system allows for more testing to be done with fewer testing personnel, thus allowing for more tuning adjustments and combustion improvement opportunities for less money. |

Click Here to Read! Click Here to Read! | March 2023 – “Shock Wave” Impulse Cleaning Device Case Study Storm Technologies, Inc. has teamed up with PowerPlus Cleaning Systems to provide IMPULSE® cleaning technology to our customers in the utility and industrial industries. The impulse cleaner is an inexpensive, low-maintenance system that generates a “shock wave” by completing the combustion of ethylene gas. The system was originally made to improve the cleaning effectiveness of standard sonic or acoustic horns and has been utilized for cleaning since 2006. From PowerPlus’ experience and what we have seen firsthand, the system works best in the convection pass versus a radiant section where a molten, sticky, or “runny” slag may be present in many industrial/utility boiler arrangements. |

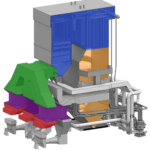

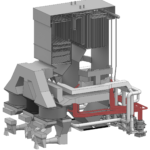

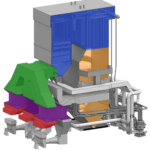

Click Here to Read! Click Here to Read! | Feb. 2023 – Storm’s Fabrication Capabilities And Outage Support Storm Technologies, Inc. is more than just testing crews pushing a probe in a boiler or pulling coal samples out of fuel lines. We have the experience and the abilities to offer resourceful solutions from engineering, design, and fabrication to technical direction, testing, and tuning services for all general boiler and combustion system components. What begins as a conceptual design, often becomes cost-effective RESULTS for our customers. We are fully committed to our mantra “QUALITY, SERVICE, RESULTS” and we are driven to all of our customers’ needs, from concept to completion. |

Click Here to Read! Click Here to Read! | Jan. 2023 – Periodic Monitoring can Prevent Forced Outages During Peak Demand Storm Technologies, Inc. has long been an advocate for performance-driven maintenance programs. By conducting routine performance testing on the coal pulverizers and boilers, small problems can be identified and often addressed before they potentially cause the unit to be derated or even worse, forced into an unplanned outage. These unplanned forced outages often come during peak power demand periods when the price per MW is high and desired for the boiler to be operated at maximum capacity with a “hands-off” operating policy. |

Click Here to Read! Click Here to Read! | In Part II of this two-part newsletter, we are highlighting two more common concerns that plants often face. The first being the rotating throat geometry. As stated in Part I of this series, Storm’s experience has been that 7,000 ft/min velocities must be maintained at the throat to keep raw coal from spilling through the throat. The second point that we will cover in this article is something that over the past ten years seems to have been at the forefront of most pulverized coal plants, and that is changing coal quality. Many plants have been fighting to stay competitive with the addition of natural gas combined cycles and the influx of renewables into the energy market. One of the easiest ways to cut the total operating cost of the plant is to switch to a lower-cost fuel; however, this can come with an array of new challenges; one of them being mill puffs. |

Click Here to Read! Click Here to Read! | It is too late to conduct preventative primary airflow calibrations or internal mill once a pulverizer puff has occurred. Storm Technologies, Inc. has been a proponent of quarterly testing programs since the company was founded in 1992. While most plants do not conduct testing this frequently, plants that do complete this testing along with performance inspections on an annual basis are much more likely to not experience a mill puff that is related to poor airflow control, throat geometry, or even a change in fuels. In this two-part technical newsletter series, we are providing several examples where these variables can cause or have caused puffs to occur. |

Specialized Resources

|

March 2024 Newsletter – “The Impact of Primary Airflow Measurement and Control on Safety, Reliability and Optimization” |

|

June 2020 Newsletter – “Airflow Management on Corner Fired Boiler” |

|

Mar. 2015 Newsletter – “Cycling of Large Utility Boilers, Some Thoughts to Consider” |

|

Oct. 2012 Newsletter – “Measurement of Combustion Airflow” |

|

Sep. 2011 Newsletter – “Airflow Measurement: The Growing Importance of Accurate and Reliable Combustion” |

|

May 2010 Newsletter – “The Benefits of Flow Nozzles and Venturies” |

|

Dec. 2009 Newsletter – “#1 Controllable Stealth Loss – Boiler Air In-Leakage” |

|

May 2009 Newsletter – “How Storm’s Resources Can Be Utilized for Measurement and Control of Airflow” |

|

Oct. 2007 Article – Power Magazine: “Managing Air to Improve Combustion Efficiency” |

|

Oct. 2006 Article – Power Magazine: “Apply the Fundamentals to Improve Emissions Performance” |

| Feb. 2021 Newsletter – “Understanding Air Preheater Performance” |

| Aug. 2016 Newsletter – “Would You Like to Better Utilize Your Outage Resources” |

| May 2013 Newsletter – “Coal Fired Boiler Optimization and the Impact on Emission Control Devices” |

| Mar. 2013 Newsletter – “Three Tips on Applying Performance Driven Maintenance” |

| Apr. 2012 Newsletter – “Maintenance vs. Manpower” |

| July 2010 Newsletter – “Invest Maintenance Dollars Wisely” |

| Dec. 2009 Newsletter – “#1 Controllable Stealth Loss – Boiler Air In-Leakage” |

| Sep. 2009 Newsletter – “The Cost Impact of Poor Airheater Performance” |

| Dec. 2008 Article – Power Magazine: “Getting the Most From Boilers, Industrial Fuels” |

| Mar. 2008 Article – World Coal Magazine: “Quality Counts” |

| Mar. 2005 Article – Power Magazine: “How stealth combustion losses lower plant efficiency” |

| Jan. 2014 Newsletter – “Is Your Plant Ready For MATS/MACT in 2014-2015?” |

| June 2012 Newsletter – “Yes, There is a War on Coal! But Somebody has to keep the lights on!” |

| Mar. 2011 Newsletter – “Meeting MACT Compliance” |

| Dec. 2009 Newsletter – “Coal Ash Chemistry Slag Management 101” |

| Aug. 2009 Newsletter – “The Impact of Furnace Performance on the Reliability of Superheater and Reheater Metals” |

| July 2009 Newsletter – “A Practical Approach to Biomass Firing” |

| June 2009 Newsletter – “Considering the Economics of Combustion Optimization” |

| Jan. 2009 Newsletter – “Four Suggested New Year’s Resolutions for Coal Plants” |

Published Articles

| Mar. 2021 | Power Magazine: “Improving Load Response and NOx Emissions with Boiler Tuning and Coal-Fired Unit Optimization” |

| Dec. 2019 | Power Magazine: “Is Chasing Grid Demand Killing Your Large Coal Boiler?” |

| Nov. 2017 | Power Magazine: “Improve Power Plant Heat Rate with a Pulverizer Performance Program” |

| Dec. 2015 | Power Magazine: “Coal Pulverizer Maintenance Improves Boiler Combustion” |

| Jun. 2015 | Power Magazine: “Typical Causes of Slagging and Fouling Problems in Boilers” |

| Jul. 2013 | World Coal: “Why Remembering the Fundamentals Can Yield Cost-Effective Results in Coal Combustion” |

| Nov. 2010 | Coalblog: “The Benefits of Applying the Fundamentals” |

| Oct. 2010 | CoalPower: “Pulverized Coal Pipe Testing and Balancing” |

| Oct. 2009 | Power Magazine: “Measuring Coal Pipe Flow” |

| Mar. 2009 | Power Magazine: “Blueprint Your Pulverizer” |

| Dec. 2008 | Power Magazine: “Getting the Most From Boilers, Industrial Fuels” |

| Oct. 2008 | Power Magazine: “Finessing Fuel Fineness” |

| Jun. 2008 | Power Magazine: “Boiler Optimization Increases Fuel Flexibility” |

| Mar. 2008 | World Coal Magazine: “Quality Counts” |

| Oct. 2007 | Power Magazine: “Managing Air to Improve Combustion Efficiency” |

| Feb. 2007 | Power Magazine: “To Optimize Performance, Begin at the Pulverizers” |

| Oct. 2006 | Power Magazine: “Apply the Fundamentals to Improve Emissions Performance” |

| Sep. 2006 | World Coal Magazine: “Crush It, Pulverize It and Burn It” |

| Mar. 2005 | Power Magazine: “How stealth combustion losses lower plant efficiency” |

Technical Papers & Presentations

| May 1997 | 3rd Annual Conference on Unburned Carbon on Utility FLyash – “Three Years Operating Experience at a NOx Limit of 0.33 lbs./ MBtu with Flyash Carbon Content Less Than 5%” |

| April 1997 | American Power Conference – “Time and Cost Effective Repairs to Boiler In-Leakage” |

| 1996 | PowerGEN – “Performance Combustion and Reliability Optimization of a 360 MW Unit Firing 90% Pulverized Coal and 10% Municipal Solid Waste” |

| 1995 | PowerGEN – “Performance Optimization of a Boiler Equipped with Low NOx Burners” |

| April 1995 | IJPGC ASME – “A Comprehensive Common Sense Approach to Low NOx Combustion in Pulverized Coal Fired Boilers” |

| April 1991 | 13th Annual Kentucky Coal Utilization Conference – “Pulverizer Coal Boiler Optimization Through Fuel / Air Control” |

| 1987 | ASME – “Coal Fired Boiler Performance Improvements Through Combustion Optimization” |