Continuous Flue Gas Monitoring System

Are you in need of on-demand measurement of O2, CO, NOx, and temperature in your furnace’s backend ductwork?

-

On-demand measurement of O2, CO, NOx and Temperature

-

Can be integrated into DCS for control room observation

-

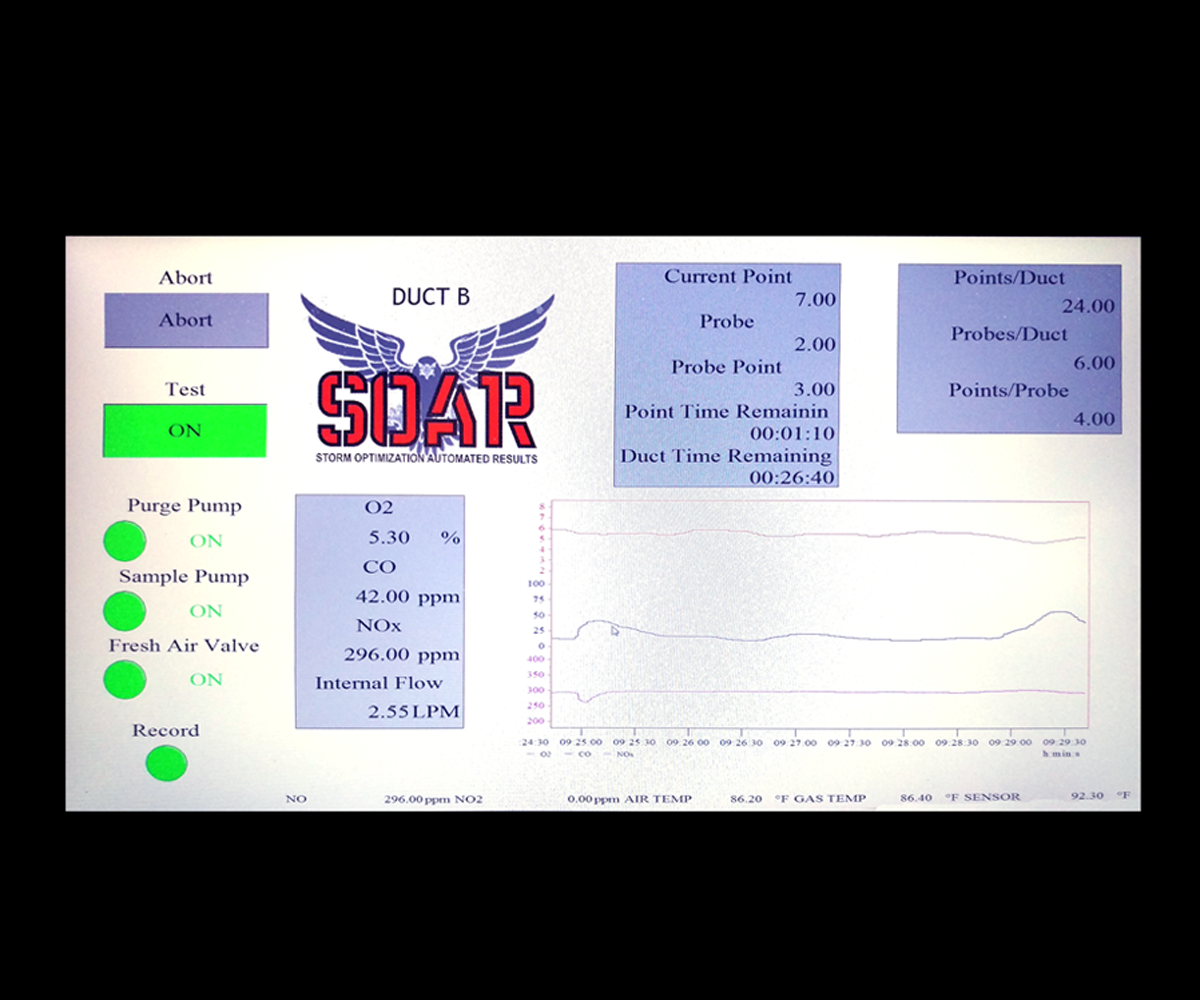

Has robust PLC system to cycle through test points controlled from user interface

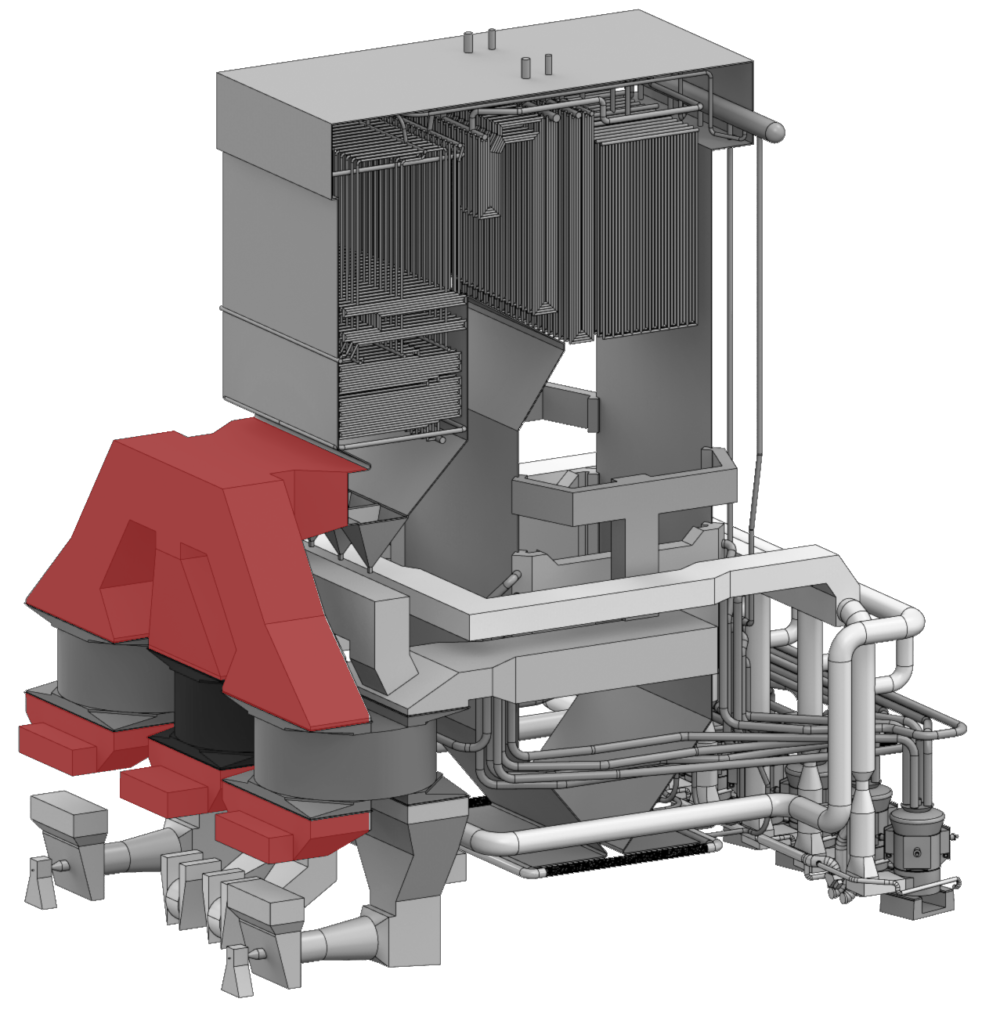

STORM’s Continuous Flue Gas Monitoring (CFGM) system is designed to provide on-demand measurements of flue gas constituents of O2, CO, NOX, and temperatures across a grid. The system will automatically cycle through the predetermined grid points and extracts a flue gas sample and temperature measurement for each respective point sequentially. Controls include a robust Programmable Logic Controller (PLC) system which cycles through each point controlled from a user interface. Test protocols can be designated by the customer, but the standard is to cycle through each point for a pre-specified period.

Sample extraction lines can be heat traced and temperature-controlled to prevent condensation until the sample conditioning system. The sample conditioning system creates a dry sample for analysis with integrated alarms for water carryover and sample temperatures. Flue gas samples are then transported to a CEM’s style analyzer which measures each point as is it cycled through during the test. The results can be integrated into the DCS so that control room operators and plant staff can quickly complete a test, view the results, and make tuning decisions in-house without the need of a large test team to conduct the testing.

Overview:

- Measures O2, CO, NOx, and Temperature

- Graphical control interface and programmable logic controls

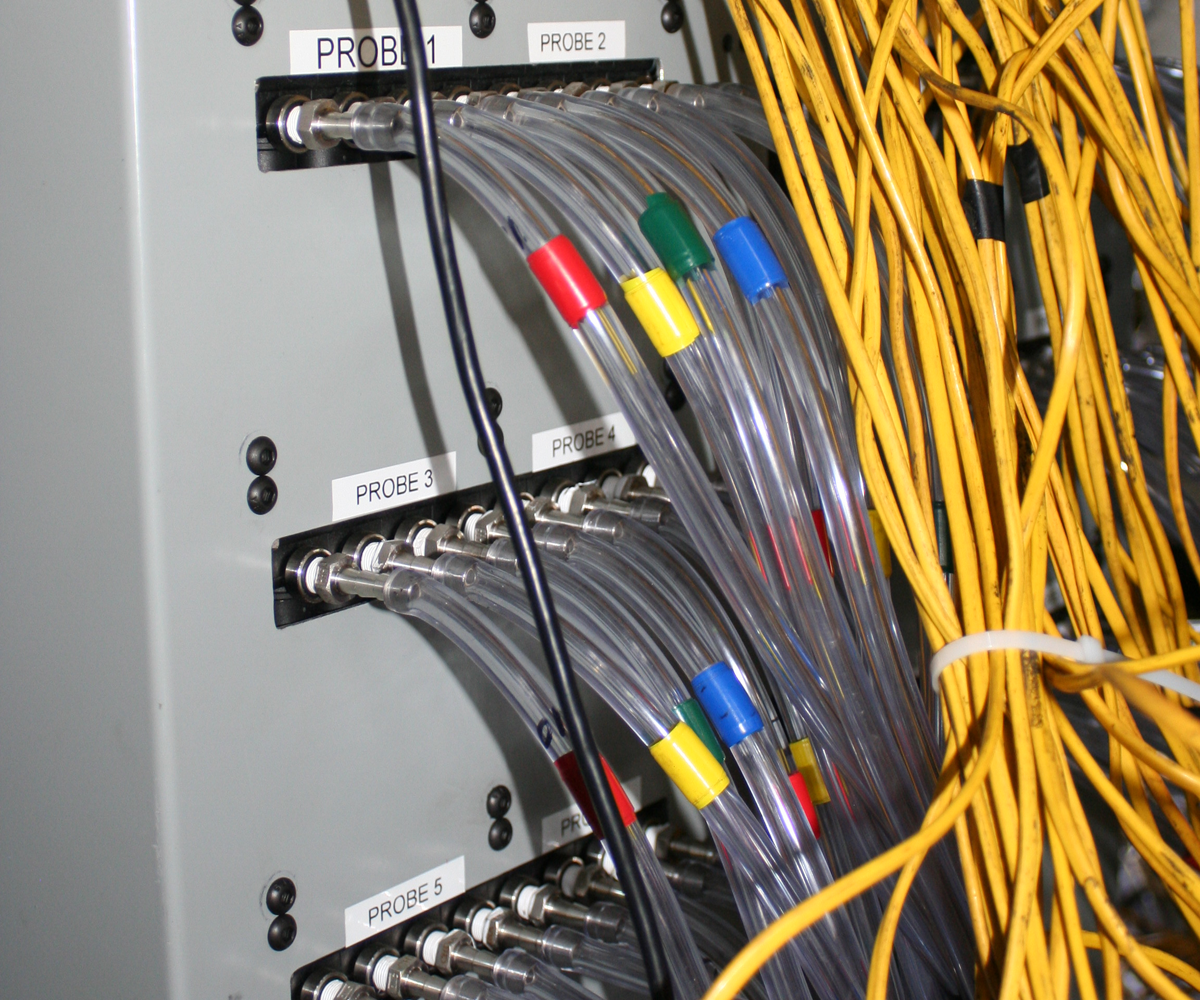

- System data logs measurements with the ability to relay information to a remote location and unit DCS for control room observation and system data logging

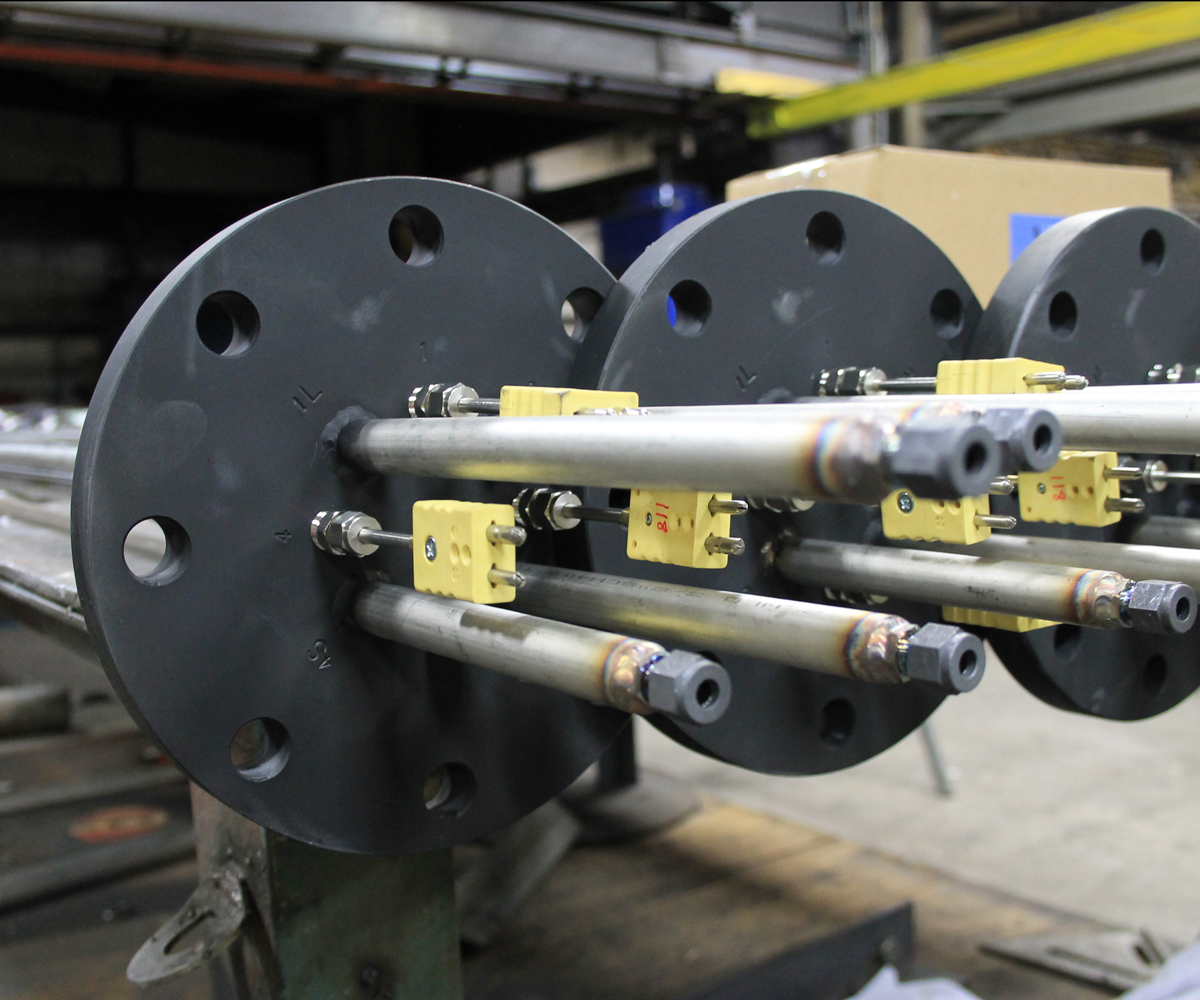

- Heavy-duty multipoint probes with replaceable probes

- Integrated filters and automated blowback system

- CEM’s style continuous analyzer

- Integrated dry gas conditioner with alarms for water and temperature

- Auxiliary (bypass) pump to reduce response time by maintaining a new sample at the cabinet

- Climate controlled cabinet

- Tubing and thermocouple cable trays

- Optional heat traced lines

Testing Locations