Pulverizer Throat Bypass System

Are your pulverizers experiencing mill rumble at low loads or higher differential pressures than wanted?

-

Increase PA capacity through the mill by reducing pressure drop

-

Maintain or improve fuel fineness by operating on the proper air/fuel ratio

-

Improved sweeping of fines from table

Do You Experience?

- High Mill Differential Pressure

- Primary Air Limitations

- Mill Capacity Issues

- Airflow Measurement & Control Issues

- Mill Rumbling

- Excessive Mill Liner Housing Wear

What are the Benefits?

- Improved sweeping of fines from table

- Reduced skidding and rumbling

- Lower mill differential pressure

- Maximum velocities lowered

- Increase Primary Air capacity through the mill by reducing pressure drop

- Accurate airflow measurement

- Maintain or improve fuel fineness by operating on the proper air/fuel ratio

How Does it Work?

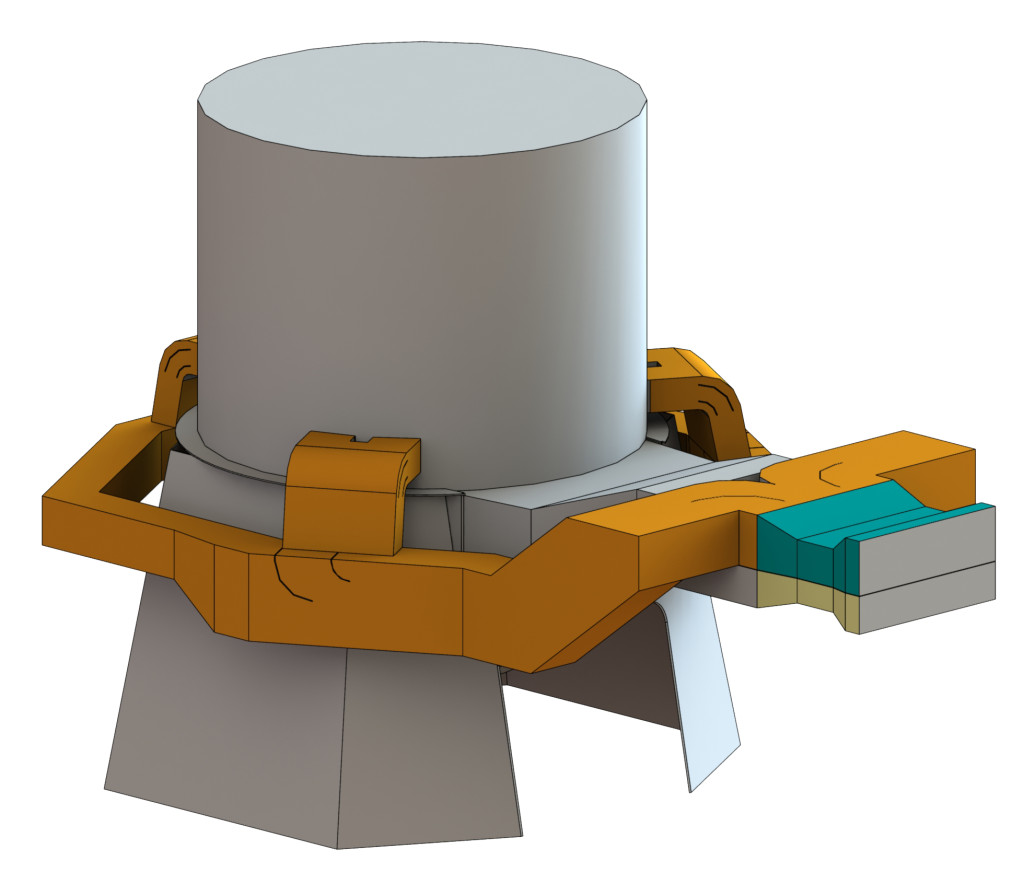

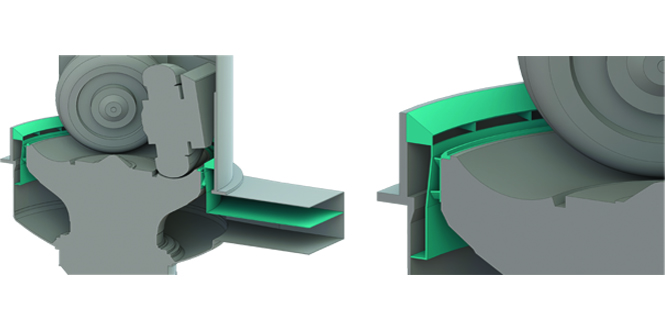

A portion of Primary Air is taken from the PA Inlet and introduced above the rotating throat through an internal chamber.

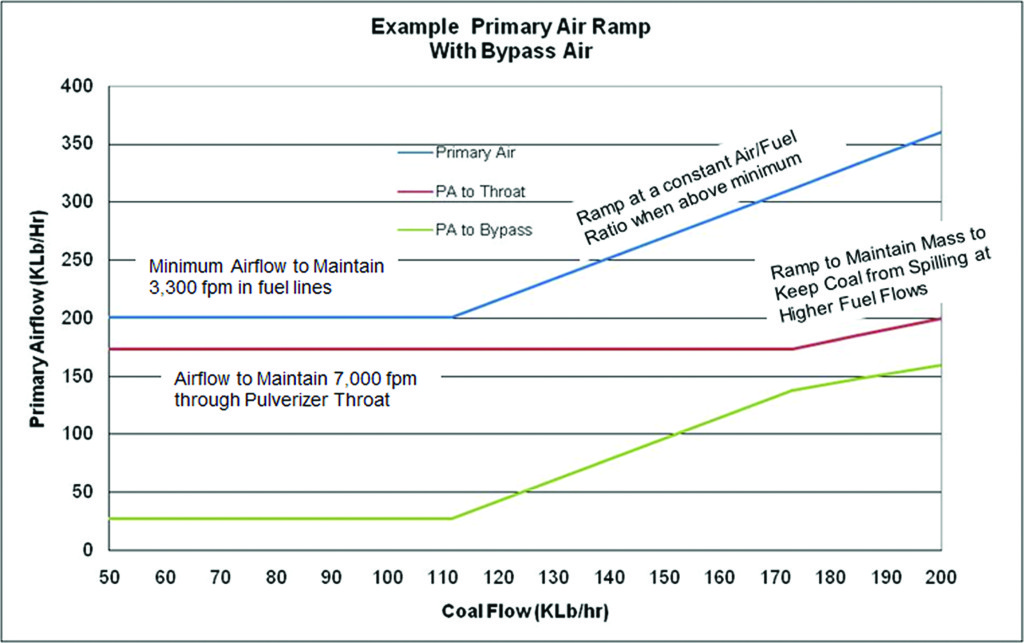

Bypass and Mill Control

The total primary airflow will be controlled as before, however, the control of the bypass flow will be modulated with a control damper driven from an installed logic curve just as the primary air curve. The curve demand will be derived from mill demand which will throttle air between the mill bypass and the throat. Venturis are utilized to accurately measure the throat and bypass airflows.

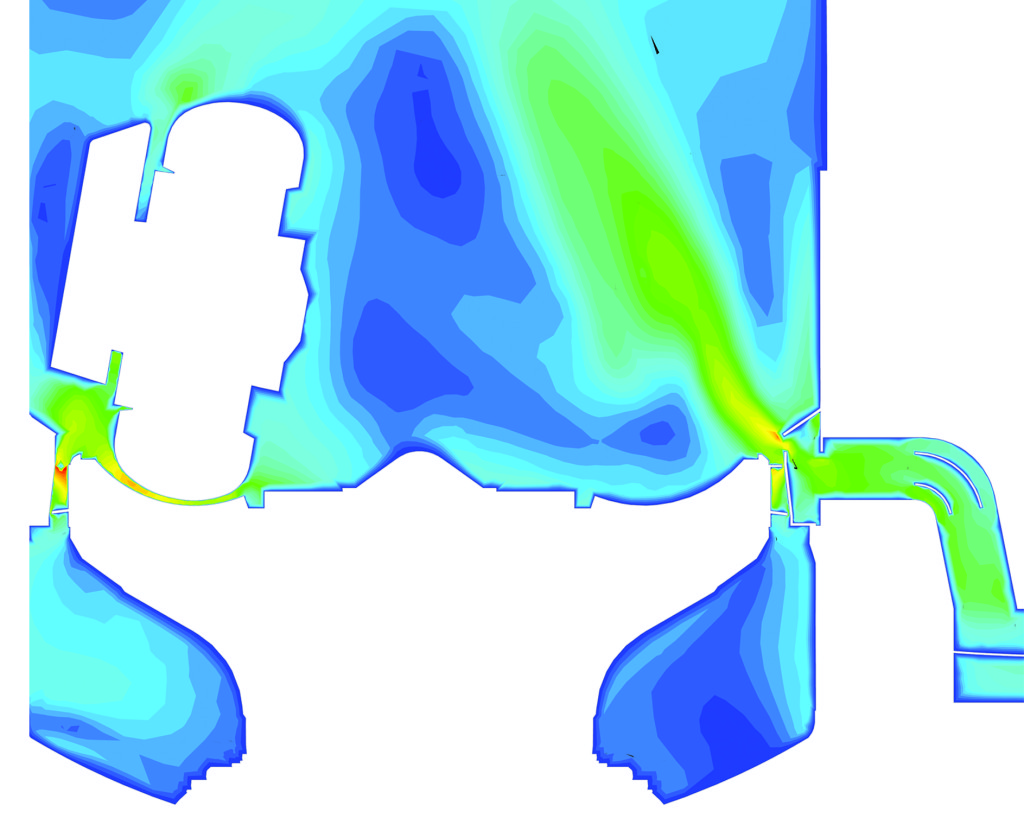

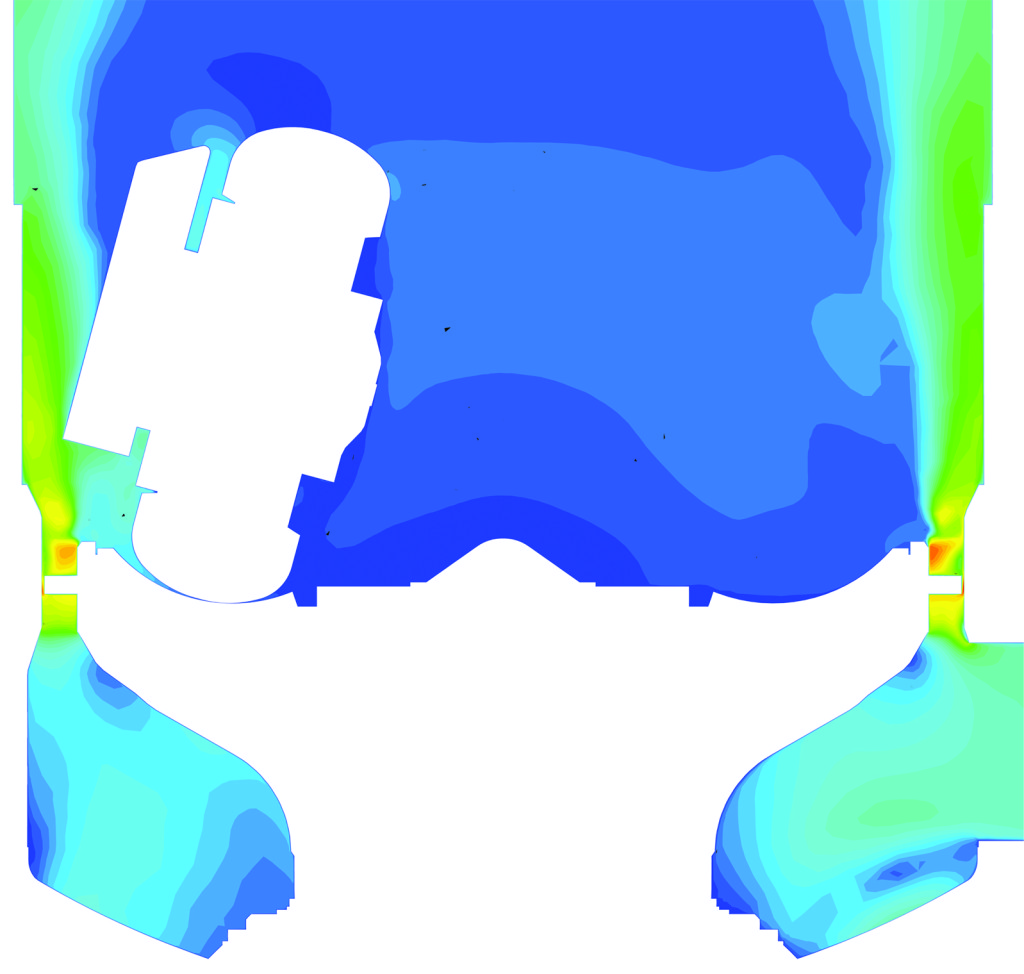

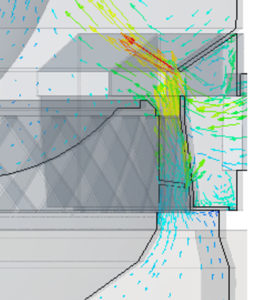

CFD Modeling

Computational Fluid Dynamics (CFD) modeling has been completed on other throat arrangements as well as STORM’s throat bypass system utilizing CD-Adapco’s Star CCM+ software. This CFD modeling was utilized to refine the design to assure reduction in differential pressure; airflow patterns to properly sweep fine coal from the grinding zone were achieved, improved airflow vectoring, minimize wear zones, and assure balanced airflow within the mill.