MATS Compliance

Let us help you maintain MATS compliance on your boiler. The EPA’s Boiler MATS rule requires your coal-fired boiler to undergo a combustion tune-up every three to five years as part of the work practice standards. This typically consists of outage inspections and post-outage combustion tuning which Storm can confidently complete.

-

Provides the plant with an opportunity to make necessary repairs to burners and combustion system

-

Combustion tune up to optimize oxygen, CO and NOx

-

Opportunity for heat rate and efficiency improvements

Mercury Air Toxics Standards (MATS)

According to the EPA’s Boiler MATS (Mercury and Air Toxic Standards) rule that was finalized in 2012 and as part of the work practice standards requires a boiler tune-up to be completed. The tune-up requirements are listed as follows:

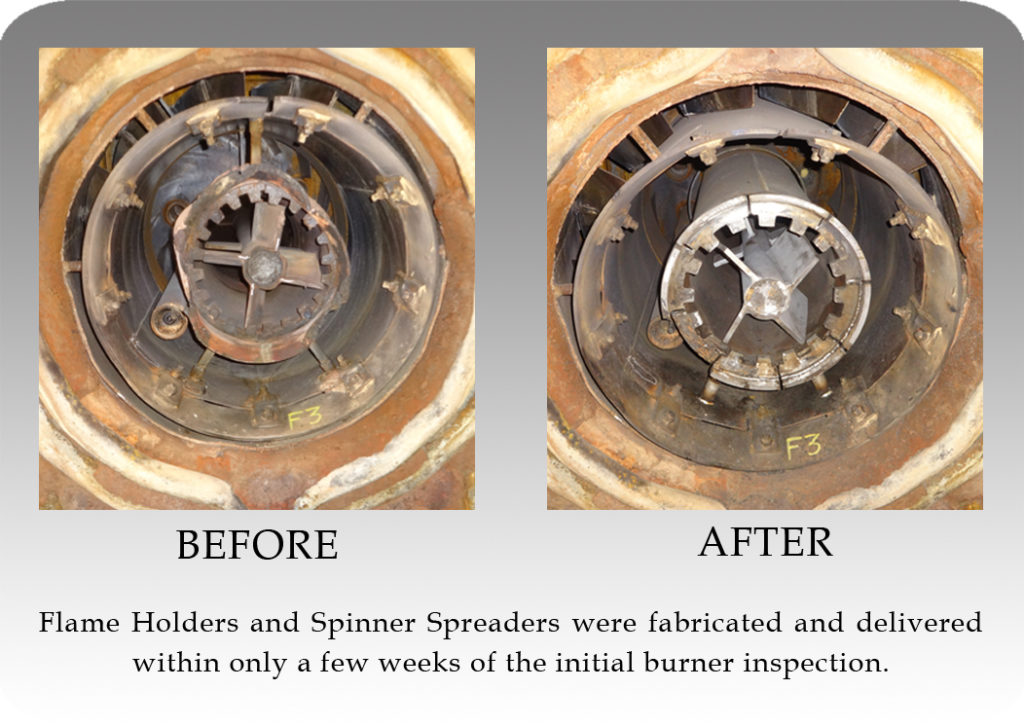

- Inspect the burners and clean, repair or replace any burner component that can affect the production of CO or NOX.

- Inspect the system controlling the air to fuel ratio and ensure that is functioning properly and calibrated.

- Inspect the flame pattern and adjust the burner as needed to optimize based on best industry practices

- Optimize the CO emissions. This should be done so as not to exceed any NOX emission limits with the boiler.

- Provide post-tune-up flue gas measurements of CO and oxygen levels in parts per million and percent volume, respectively.

- Provide a written report to be maintained onsite that details the flue gas measurements following the tune-up of the boiler and any of the actions taken to tune the boiler.

Storm’s team of professionals have successfully been conducting the work practice standards associated with the boiler tune-ups and inspections since the MATS rule was implemented on various size boilers across the country. If your plant is equipped with multi-point probes or has the ports available for multi-point probes to be installed, Storm can utilize its automated flue gas sampling system (SOAR) and conduct the combustion tune-ups with minimal manpower. The automated sampler cuts down on the test times allowing for more tests to be completed in a single day to reduce the overall manhours required.