Applied Engineered Solutions

Our team is accustomed to taking a project from a concept to an engineered solution, including FEA and CFD analysis, in a timely and accurate manner in order to meet our customers’ stringent schedule needs. Each customized project is directed towards STORM’s primary intention of being customer and RESULTS driven.

-

Consultations, review, and design with CAD, CFD and FEA analysis

-

In-house fabrication capabilities for cost-effective options

-

Technical direction for installations & inspections along with testing teams for field verifications & calibrations

Our Engineering and Fabrication department is comprised of engineers, designers, and drafters with decades of combined experience. The STORM® forte is to combine the experience of senior engineers with the youthful energy and exuberance of recent graduate engineers, designers, and field technical service personnel in order to provide the unique advantage of years of experience while remaining technologically current.

Our team is accustomed to taking a project from a concept to an engineered solution in a timely and accurate manner in order to meet our customers’ stringent schedule needs. Each customized project is directed towards STORM®‘s primary intention of being customer and RESULTS driven. Our emphasis is on applying the fundamentals with regard to combustion and steam power systems by applying the “Thirteen Essentials for Optimum Combustion with Low NOx Burners” to address both performance (LOI, Heat-Rate, Spray flows, Slagging, etc…) and NOx emission levels.

Storm Technologies, Inc. strives for continuous improvement and to utilize the latest technology in CAD, FEA, and CFD software. Our experienced team is capable of meeting and exceeding all of our customers’ needs with 100% Service, Quality, and Results. After creating a concept and design of each specialized component, our fabrication and quality control efforts provide fast, reliable, and quality work for each specialized project.

STORM's Concept to Completion Approach

Initial Consult

STORM can visit your plant site; review existing components and constraints; and review drawings, operating conditions, and other information to assist in determining the best plan of action.

Design

Combining our collective decades of experience and engineering knowledge, STORM will design the best solution for the problem at hand. Using SolidWorks and AutoCAD computer aided drafting (CAD) software, STORM will then create drawing packages and 3D models for review, approvals, fabrication and installation.

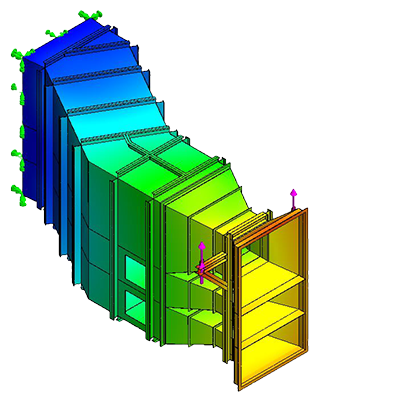

Stress/Deflection Analysis

Should extreme operating temperatures or loads develop into a design concern, STORM can use the built-in finite element analysis (FEA) simulation software found in SolidWorks to run stress analysis to ensure our designs meet a minimum factor of safety.

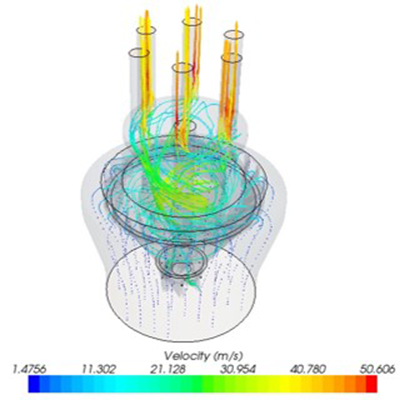

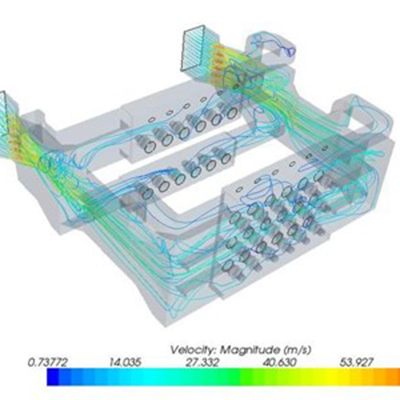

Flow Analysis

Should the airflow vectoring or temperature stratification become a concern during design, we can utilize our computational fluid dynamics (CFD) software to optimize the design and have a “real world” expectation of how the design will operate in the plant.

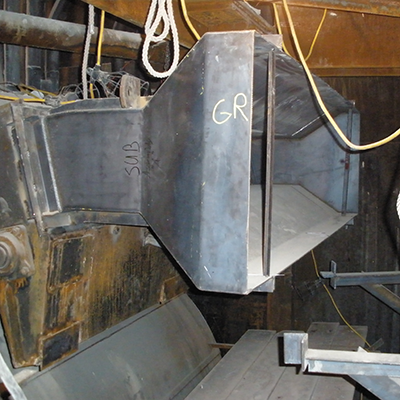

Fabrication

Once the design and drawing are complete, it is time to start cutting and welding steel. STORM has in house fabrication capabilities to manufacture our designs.

Technical Direction

Once fabrication is complete and should you require additional support for the installation, STORM can offer technical direction services to ensure that everything is installed correctly.

Testing Services

Once installed, it is necessary to make sure that all components are operating as intended. STORM offers optional testing services to ensure everything is running as intended.