Airflow Measurement & Management Systems

How accurately are you measuring airflow? Through testing and calibration on many boilers, we have found the airflow to not be accurately measured or reliable. It is necessary to accurately measure and control the airflow in order to optimize combustion.

-

Improved unit and pulverizer controllability by improving the “K” factor accuracy and repeatability

-

Smoother differential signal

-

Capability to improve DCS logic and control curves so that an optimum airflow can be achieved across the normal operating load range

STORM® has vast experience in the design, fabrication, and calibration of many different types of airflow measurement devices. We frequently find that plants are unaware of poor airflow management and control. An essential first step to good air management is the metering and proper distribution of the air.

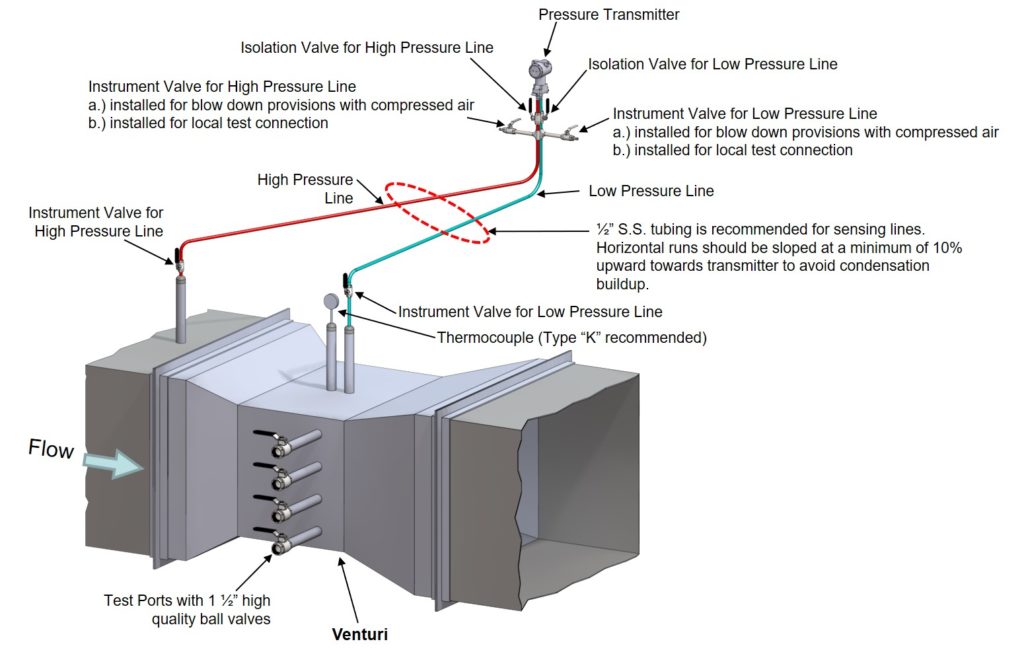

Depending on the location in the ductwork, venturis or flow nozzles are preferred for airflow measurment. In most cases ductwork is rectangular, but when possible a circular venturi is preferred for the smoothest signal and maximum pressure recovery.

Averaging pitot tubes are economical, functional, and can be accurate–depending on the flow conditions. However, with averaging pitot tubes, we have found laminar flow to be the key to repeatable and accurate tube measurements. This can be accomplished by careful flow straightening and increasing the velocity in the averaging pitot tube measurement plane. The setup should be accurately calibrated by a multi-point hand traverse and checked periodically to ensure proper quantification and control of primary and secondary air distribution.

Secondary Airflow

Accurate measurement of the secondary airflow is equally important as the primary airflow measurement in achieving optimum combustion. Accurate secondary airflow measurement is needed to be within ±3% to supply equal amounts of airflow to each burner compartment. Unequal distribution of the secondary airflow will cause high furnace exit gas temperatures and secondary combustion, which will cause overheating problems in the back-pass as well as poor unit performance.

Primary Airflow

It is necessary to accurately measure the primary airflow and coal flow for control and maintain an accurate air/fuel ratio. From testing at some plants, it has been found that the air/fuel ratio is twice as much as required, which adversely affects fuel fineness and distribution. Pulverizer optimization is the first major and necessary step in achieving optimum combustion and accurate measurement of the primary airflow to the pulverizer. Primary airflow shall be accurately measured & controlled to ±3% accuracy.

Overfire Air

Accurate measurement of the overfire airflow is equally important as the primary airflow measurement in achieving optimum combustion. Accurate secondary airflow measurement is needed to be within ±3% to supply equal amounts of airflow to each airflow compartment.